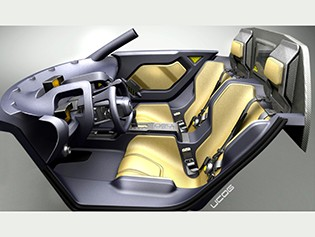

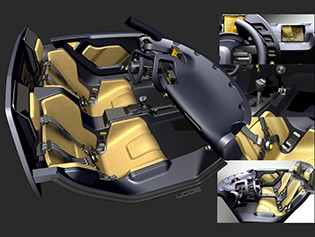

The Automotive interior industry

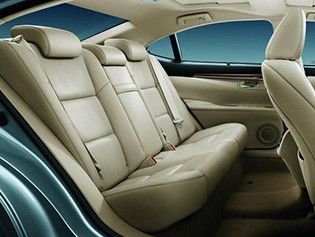

The car mat cutting machine produced by Dmais not only has high cutting accuracy and fast cutting speed, but more importantly, it can be used for multiple purposes. A set of advanced and quickly replaceable knives has unparalleled diversity, and different knife heads are configured according to the needs of various processing materials. The DMS-2516 mat cutting machine can not only be used to produce mats, but also for qualitative cutting of seat covers, trunk mats, and light-shielding mats. It is also suitable for cutting a variety of materials, including various leather materials, cloth and other non-metallic materials. As long as you have a mat cutting machine, you can open a car interior processing plant, and buying a mat cutting machine will also give you a free template file.

Dmais provides integrated cutting solutions for automotive interiors/mats/bags

Dmais Cutting is a double-knife seat automatic feeding intelligent cutting machine developed by our company in response to market demand for special industries such as car cushions, car interiors, car mats, etc. The outstanding features of this machine are low cost, high efficiency, high return, high degree of automation, automatic material laying, automatic continuous processing, suitable for large-scale processing and production, greatly saving space and labor.

Applicable materials: leather, cloth, wool, flexible materials, synthetic materials, suitable for wool pads, four-season pads, sandwich multi-layer pads and other materials. Car large surround mats, wire loop mats, plush carpets, imported thick EVA rubber-bottomed carpets, latex mats, PVC mats, TPE rubber mats, imitation leather, composite cotton, seat cover cutting.

It is widely used in the automotive supplies industry and is deeply loved by manufacturers. There are abundant double-knife head tools, blade cutting, full cutting, half cutting, and line drawing. The drawing reader automatically recognizes the template conversion CAD and other formats, automatic typesetting, automatic nesting, automatic cutting, and automatic feeding.

Suitable tools & application materials

Two khaki car floor mats

Machine head design

Adopts the convenient replaceable machine head design concept, and can replace and add tool heads with different functions according to actual needs

Communication interface

The data interface is a gigabit network interface, which can realize remote upgrade and maintenance, with fast transmission speed and long distance.

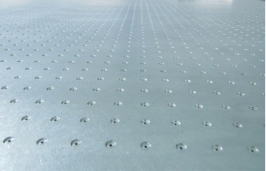

Table design

Adopting advanced and mature rolling table design, aluminum "honeycomb" vacuum adsorption platform, maintains a flat cutting platform and improves cutting accuracy.

Control system

Self-developed human-machine interface operating system, humanized design, intelligent identification of knife cutting, and quick capture of cutting targets.

Imported felt

Imported felt is used, which is wear-resistant and breathable, ensuring the high flatness of the cutting platform.

Infrared anti-collision system

Safety anti-collision system ensures the safety of operators.

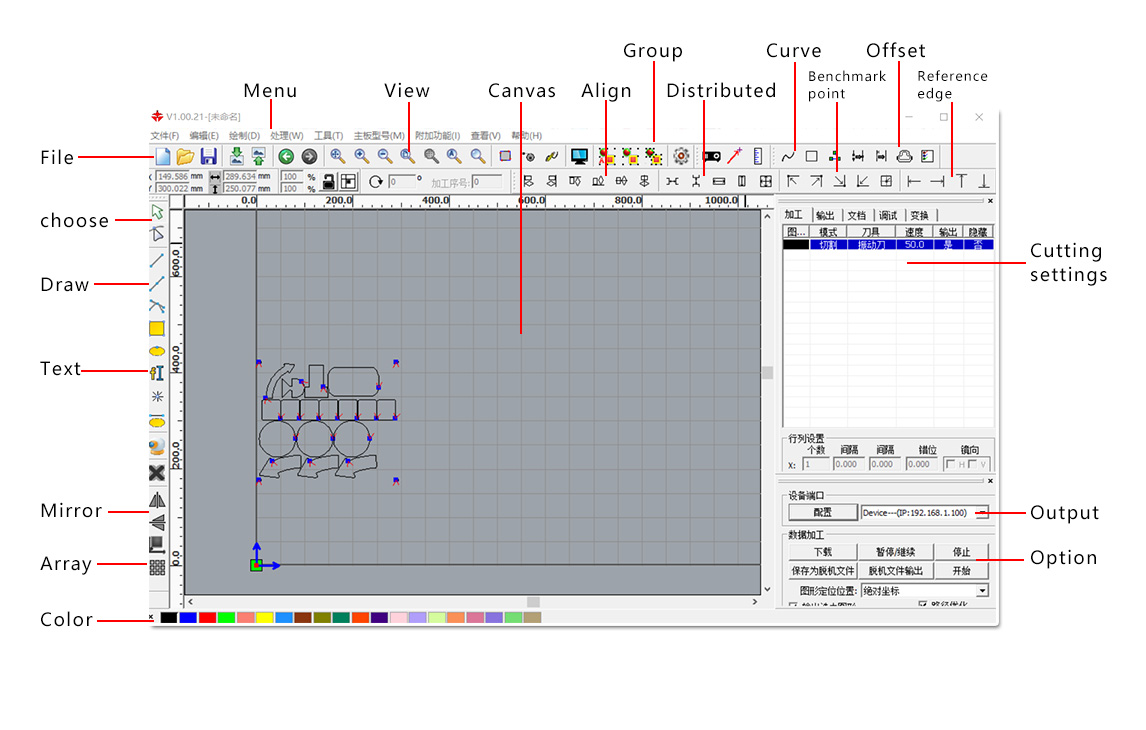

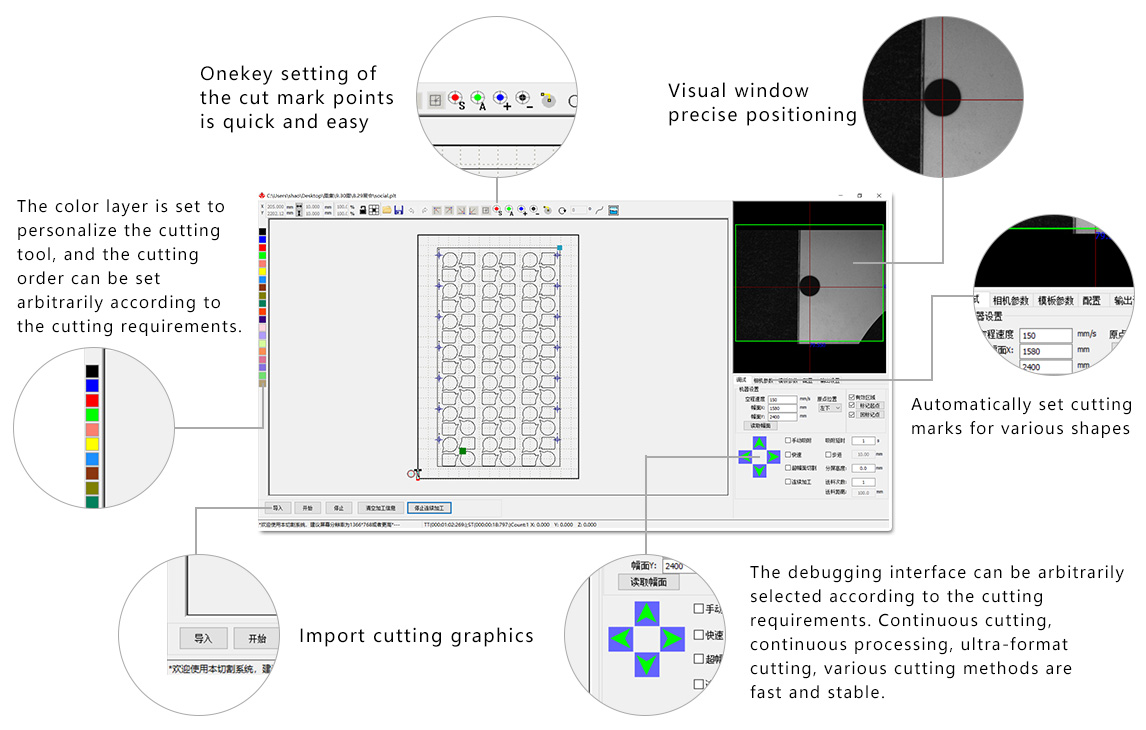

Digital cutting machine software features

The Dimais digital cutting machine uses self-developed CAM software, and user needs are perfectly integrated into the software design. It is a fully automatic intelligent cutting system that integrates the three advantages of performance, speed and quality. It can quickly complete various processes such as full cutting, half cutting, milling, punching, creases, marking, etc. It is simple and convenient to operate, with rich and practical functions, and can meet user customization needs with the tool quick change module.

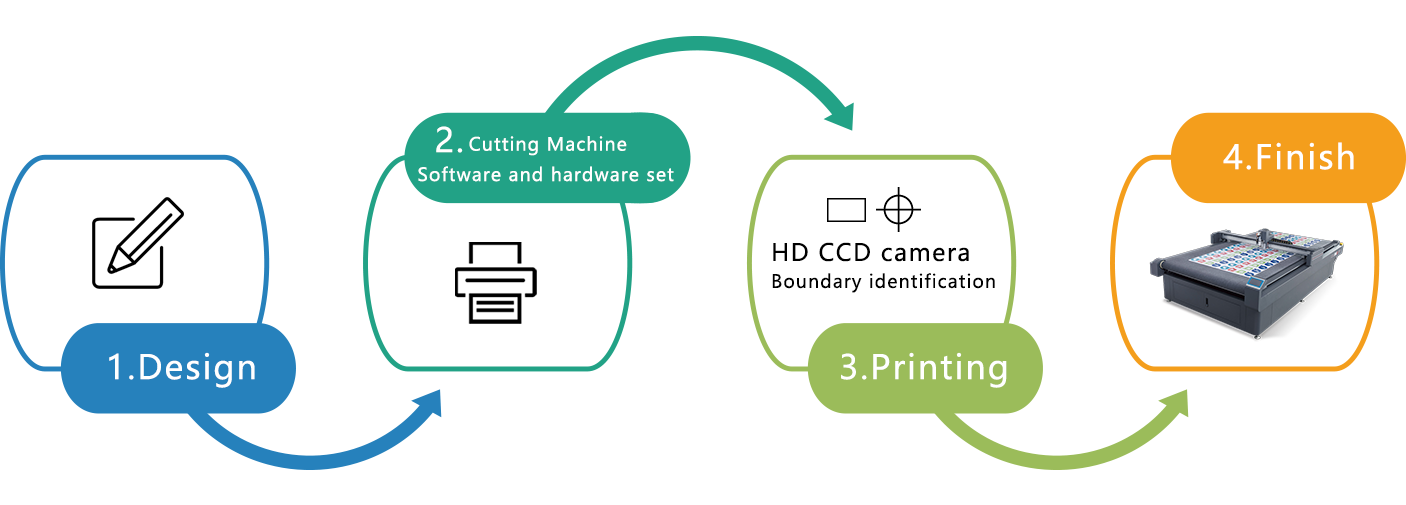

Cutting process diagram

Automotive interior industry cutting machine computer cutting machineTechnical Parameters

| Technical Parameters/Model | DMS-2516A |

|---|---|

| Functionality | Convenient tool changes, equipped with vibrating blade, cutting, half-cutting, and embossing functions, graphic and standard positioning with optional CCD positioning for industrial machine positioning |

| Safety Equipment | Safety monitoring system |

| Horizontal Speed | 800-1500 mm/sec |

| Cutting Speed | 200-1200 mm/s (depending on different cutting materials) |

| Cutting Depth | 40mm (depending on different cutting materials) |

| Material Fixed Method | Vacuum adsorption |

| Cutting Accuracy | ±0.05 mm |

| Repeatability | ±0.01 mm |

| Service Life | Based on network |

| Transmission Interface | ≤350 m |

| Network Transmission Distance | 2GB |

| Network Cable | Digital service return, direct line guide, step belt, silk red, and axle wheel |

| Transmission System | 7.5-11 Hz |

| Efficiency | 380V ±10% |

| Power Supply | 2500×1600 mm |

| Working Range | 1600 mm |

| Maximum Cutting Thickness | 3521×2186×1280 mm |

| Product Dimensions | 3670×2340×1500 mm |

| Packaging Dimensions | 1150 kg |